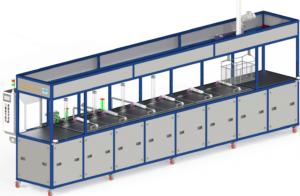

Ultrasonic Cleaning Machine

Ultrasonic Parts Washer for Deep Cleaning of Complex Components

An ultrasonic parts washer uses high‑frequency sound waves in a liquid bath to remove oil, grease, carbon, chips and fine particulate from parts, even in blind holes and hard‑to‑reach areas. Cavitation bubbles generated by the ultrasonics implode on the surface of the part, dislodging contamination without damaging the substrate.

Configured as an industrial ultrasonic cleaning machine, this technology is ideal for precision components in automotive, aerospace, medical, electronics and general engineering where conventional spray washing struggles to reach internal features.

How an Ultrasonic Parts Washer Works

In an ultrasonic washer, transducers bonded to the tank convert electrical energy into high‑frequency sound waves, typically around 25–40 kHz or higher. These waves create microscopic cavitation bubbles in the cleaning fluid, which collapse and create tiny jets that strip contaminants from the part surface.

Because the energy is distributed throughout the bath, a large ultrasonic cleaner can clean many small parts at once or larger components, ensuring uniform cleaning inside holes, slots and fine geometries that are difficult to reach with brushes or spray nozzles.

Industrial Ultrasonic Cleaning Machine – Key Advantages

Using an industrial ultrasonic cleaning machine brings several performance and process benefits:

- Superior penetration: Ultrasonics reach into blind holes, capillaries and complex passages that spray systems may miss.

- Gentle but effective: The process is powerful on contamination yet gentle on delicate parts, coatings and threads.

- Reduced manual labour: Once parts are loaded, the ultrasonic parts washer runs automatically, reducing hand cleaning and rework.

For high‑throughput needs, multi‑stage systems can combine pre‑wash, ultrasonic cleaning, rinsing and drying in a single automated line.

Large Ultrasonic Cleaner for Heavy-Duty Applications

A large ultrasonic cleaner is designed for bigger parts or high batch quantities, with tank capacities ranging from tens to thousands of litres. These systems often include hoists, platforms or automated loading to handle heavy components safely.

In heavy engineering, the ultrasonic washer can clean gear housings, hydraulic blocks, tooling and fixtures, while still providing the same deep‑clean effect in internal passages that smaller benchtop units deliver.

Automotive Ultrasonic Cleaner Applications

As an automotive ultrasonic cleaner, the system is widely used for:

- Engine components such as pistons, cylinder heads, valves and injectors.

- Transmission parts, brake components and steering system parts where carbon and varnish are common.

- Cleaning of delicate aluminium or precision components without harsh mechanical scrubbing.

By removing stubborn deposits and fine contamination, an ultrasonic parts washer extends component life and improves performance in automotive and similar industries.

Ultrasonic Parts Washer – Typical Specifications

Align values to your standard models:

|

Specification |

Value (example) |

Notes |

|

Machine type |

Single or multi‑tank ultrasonic parts washer |

Bench or floor-standing |

|

Tank volume |

50–1000 litres |

Larger for heavy-duty models |

|

Ultrasonic frequency |

25–40 kHz (single or multi-frequency) |

Tuned to contamination and parts |

|

Power density |

10–20 W/litre (typical) |

Higher for heavy contamination |

|

Heating system |

Electric heaters with digital control |

40–75 °C operating range |

|

Process stages |

Ultrasonic wash / Rinse / Optional dry |

Single or multi‑stage |

|

Basket/load capacity |

50–500 kg per basket |

Depends on large ultrasonic cleaner design |

|

Controls |

PLC / digital timer and temperature control |

Recipe‑based operation |

|

Construction |

Stainless steel tank and frame |

Industrial duty |

|

Options |

Filtration, oil skimming, agitation, dryers |

For demanding applications |

When to Choose an Ultrasonic Parts Washer vs Spray Washer

You should consider an ultrasonic parts washer when:

- Parts have complex internal passages, fine features or blind holes that spray cannot reach.

- You need precision cleaning before coating, bonding or assembly in critical industries.

- Manual cleaning is too slow, inconsistent or labour‑intensive, especially for delicate parts.

Spray systems are still effective for simple geometries and heavy bulk contamination, but an industrial ultrasonic cleaning machine is the better choice for precision and complexity.

Frequently Asked Questions

What types of contaminants can an ultrasonic parts washer remove?

An ultrasonic parts washer can remove oils, greases, cutting fluids, carbon deposits, rust, polishing compounds and fine particulate. Cavitation dislodges these contaminants from surfaces and crevices, making it effective for complex industrial and automotive parts.

Are ultrasonic parts washers safe for delicate components?

Yes. When operated with the correct frequency, power and chemistry, an ultrasonic washer is safe for delicate components, including aluminium parts, fine threads, precision machined features and many coated surfaces. The process relies on microscopic cavitation rather than aggressive mechanical scrubbing.

How do I size a large ultrasonic cleaner for my application?

To size a large ultrasonic cleaner, define maximum part dimensions, batch quantity, contamination type and required cycle time. From this, tank volume, basket size, ultrasonic power and heating capacity are specified so the industrial ultrasonic cleaning machine meets your throughput and cleanliness requirements.

Can an ultrasonic parts washer be used in automotive workshops?

Yes. As an automotive ultrasonic cleaner, the machine is ideal for deep cleaning engine, fuel and brake components in workshops and remanufacturing facilities. It removes carbon, varnish and stubborn residues far more effectively than manual methods, often in a fraction of the time.

What maintenance does an industrial ultrasonic cleaning machine require?

Routine maintenance includes checking fluid level and chemistry, cleaning filters, removing sludge from the tank, inspecting transducers and verifying heaters and controls. Regular maintenance ensures the industrial ultrasonic cleaning machine maintains consistent cleaning performance and extends equipment life.

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |