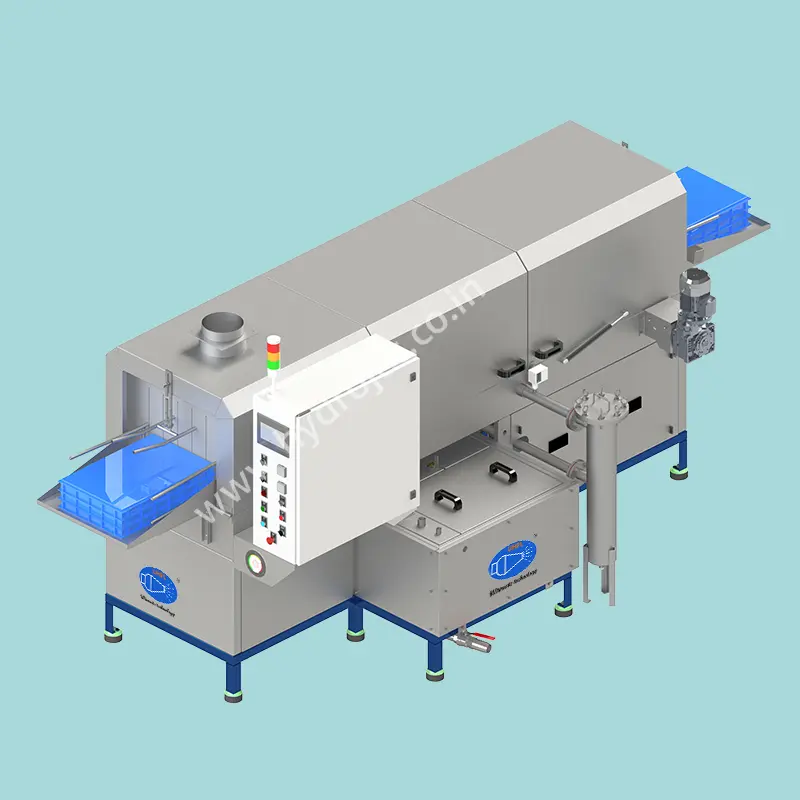

Conveyorized Type Crate Washing Machine

Conveyorized Type Bin / Crate Washing Machine

The Conveyorized Tunnel Type Plastic Crates Washing machine expertly crafted is a low cost, highly efficient system designed with modular components allowing multiple configurations to handle vide range of plastic crates to clean effectively. This tunnel type plastic crates washing machines will be designed at various configuration according to the cleaning level requirements, dryness level requirements to the various types of industries depending upon the contamination & productivity level.

This Tunnel Type plastic crates washing machine consist of various cleaning process such as spray washing, recirculated rinsing, fresh water rinsing, compressed air blowing and recirculated hot air blowing. This machine will be able to clean at least 100 to 500 plastic crates per hour and this machine will clean the plastic crates to NASS level of cleaning standards. This machine is highly process reliable.

- Highly automated and ensure high process reliability

- In this machine plastic crates can be fed manually and unload

- Can be loaded automatically also

- Cleaned crates be returned to operate, which reduces the manpower requirements.

- Easy operational

- Easy maintenance

- PLC base control system

- Oil separator

- Pre soaking tank

- Machine drip tray

- Duplex filtration system

- Cleaning chemical

- Plastic Crates Cleaning Machine

- Crates Washing Machine

- Bin Cleaning Machine

- Bin Washing Machine

- Tray Cleaning Machine

- Tray Washing Machine

- Plastic Box Cleaning Machine

- Plastic Crates cleaning in Automotive industry

- Plastic Crates cleaning in Pharmaceutical industry

- Plastic Crates cleaning in Milk industry

- Plastic Crates Cleaning in Food industry

- Plastic Crates cleaning in shrimp industry

- Plastic Crates in logistics industry

- Plastic crates cleaning in fisheries industry.

- Baking oven tray cleaning

Conveyor Parts Washer: Streamlining the Cleaning Process for Optimal Efficiency

In many industrial settings, maintaining clean and functional parts is essential for smooth operations and product quality. A conveyor parts washer provides an automated solution to clean parts efficiently, enhancing productivity and reducing downtime. In this guide, we’ll explore the benefits of using a conveyor parts washer, how it works, and what to consider when choosing the right one for your needs.

Benefits of a Conveyor Parts Washer

- Automation: Continuous, automated cleaning process reduces manual labor.

- Efficiency: Cleans multiple parts simultaneously, saving time and resources.

- Consistency: Provides uniform cleaning results, ensuring all parts meet quality standards.

- Versatility: Suitable for a wide range of parts and industries.

How a Conveyor Parts Washer Works

A conveyor parts washer operates by moving parts through a series of cleaning stages on a conveyor belt. The typical process includes:

- Loading: Parts are placed on the conveyor belt, which moves them through the washer.

- Pre-Wash: Initial rinsing to remove loose dirt and debris.

- Washing: High-pressure jets and detergents thoroughly clean the parts.

- Rinsing: Clean water rinses off any remaining detergent and contaminants.

- Drying: Heated air or blowers dry the parts, making them ready for immediate use.

Industrial Conveyor Parts Washer: Heavy-Duty Cleaning for Large-Scale Operations

For large-scale industrial applications, an industrial conveyor parts washer is essential. These machines are designed to handle high volumes of parts, providing powerful cleaning capabilities that meet the demands of heavy-duty environments.

Key Features of Industrial Conveyor Parts Washers

- High Capacity: Capable of cleaning large quantities of parts in a continuous process.

- Robust Construction: Built with durable materials to withstand harsh industrial conditions.

- Customizable Settings: Adjustable cleaning cycles and settings to accommodate different types of parts and levels of contamination.

- Energy Efficiency: Designed to minimize energy consumption while delivering powerful cleaning performance.

Advantages of Using an Industrial Conveyor Parts Washer

- Increased Productivity: Automated cleaning process allows workers to focus on other tasks, boosting overall productivity.

- Consistent Quality: Ensures all parts are cleaned to the same high standard, reducing the risk of defects.

- Cost Savings: Reduces the need for manual labor and minimizes downtime, leading to significant cost savings.

- Environmental Benefits: Modern washers use eco-friendly detergents and water recycling systems, reducing environmental impact.

Choosing the Right Conveyor Parts Washer for Your Needs

When selecting a conveyor parts washer or an industrial conveyor parts washer, consider the following factors:

- Type of Parts: Ensure the washer is suitable for the size, material, and complexity of the parts you need to clean.

- Cleaning Requirements: Determine the level of cleanliness required and choose a washer that can meet those standards.

- Throughput: Assess the volume of parts that need to be cleaned and choose a washer with the appropriate capacity.

- Space Availability: Consider the available space in your facility and choose a washer that fits within those constraints.

- Maintenance and Support: Look for washers that are easy to maintain and come with reliable customer support and service options.

Conclusion

Conveyor parts washers and industrial conveyor parts washers offer automated, efficient, and consistent cleaning solutions for a variety of industrial applications. By investing in the right washer for your needs, you can enhance productivity, ensure product quality, and achieve significant cost savings.

For more information on conveyor parts washers and industrial conveyor parts washers, contact Ultramax. We’re here to help you find the perfect cleaning solution to keep your operations running smoothly and efficiently.

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |