Automotive Parts Washing Machine

Automotive Parts Washing Machines for High-Cleanliness Components

Modern OEMs and Tier‑1 suppliers rely on automotive parts washing machines to remove oil, chips, dust and machining contaminants before assembly, coating or packaging. These systems replace manual cleaning with an engineered parts washer that delivers consistent, measurable cleanliness on every component.

Each installation is configured as a robust parts cleaning machine for engine, transmission and chassis parts, helping you meet strict cleanliness specifications while improving throughput and reducing operating cost.

Why Automotive Parts Washing Machines Are Critical in Production

Automotive components pass through multiple machining, grinding and assembly operations, and every stage can introduce contamination that affects product life, NVH and warranty performance. A dedicated industrial parts washer ensures that each part reaches the required cleanliness level before moving to the next process.By automating wash, rinse and drying, an automatic parts washer stabilises cycle times and eliminates variation between shifts, while also allowing you to monitor temperature, pressure and chemistry for audits and traceability.

Types of Automotive Parts Washers We Offer

Different lines and components require different machine configurations, so a single generic parts washer will not fit every application. Typical automotive parts washing machine configurations include:

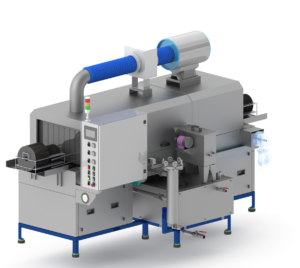

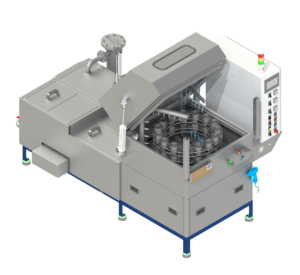

- Rotary basket and cabinet‑type parts washers for batch cleaning of small and medium components such as gears, shafts and brackets.

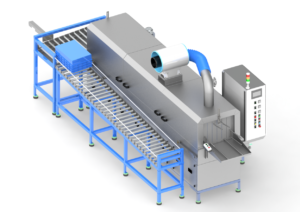

- Conveyorised industrial parts washing machines for inline cleaning between machining cells or assembly stations.

- Custom component washing machines designed around engine blocks, cylinder heads, gear housings or knuckles with complex internal geometries.

- Each auto parts washer can use spray, immersion or a combination of both, with optional ultrasonic modules when very fine contamination or blind holes are critical.

Key Features of Our Industrial Parts Washing Machines

Our industrial parts washing machines are designed for continuous operation in demanding automotive environments, with a focus on reliability, service access and low total cost of ownership. Key features often include:

- PLC‑based controls with recipe management for different components.

- Multi‑stage filtration to protect pumps and maintain bath quality in the parts cleaning machine.

- Oil separation and skimming to extend bath life and reduce detergent consumption.

- Efficient blow‑off or hot‑air drying so that parts exit the automatic parts washer dry and ready for the next operation.

For heavy workloads, we engineer heavy-duty parts washers with reinforced structures, high‑capacity pumps, and high‑efficiency heating and insulation for lower energy use.

Typical Automotive Components We Clean

A well‑designed component washing machine can handle a wide range of automotive parts without compromising on cleanliness or cycle time. Typical parts processed include:

- Engine blocks, cylinder heads, crankshafts and camshafts.

- Gear shafts, housings, differential casings and transmission components.

- Brake components, steering knuckles, control arms and suspension parts.

- Precision turned and ground components that require strict particulate control.

Fixtures, baskets and spray manifolds are engineered so that the parts washer delivers uniform impact and coverage, ensuring blind holes, galleries and sealing surfaces are thoroughly cleaned and dried.

Benefits of an Automatic Parts Washer for Automotive Plants

Deploying an automatic parts washer provides more than just cleanliness; it directly impacts productivity and quality. Main benefits for automotive plants include:

- Reduced manual handling and labour costs through automation of the entire wash–rinse–dry sequence.

- Stable, repeatable results from a controlled industrial parts washer, improving first‑pass yield and reducing rework.

- Easier compliance with OEM cleanliness standards and internal quality systems through data logging and recipe control.

By combining robust mechanical design with process know‑how, each automotive parts washing machine is tuned for your contamination level, cycle time and available floor space.

Why Choose Our Automotive Parts Cleaning Machines?

Choosing the right automotive parts washing machine means balancing cleanliness, throughput and long‑term operating cost.

Working from your sample components and technical requirements, our team selects the appropriate industrial parts washer concept, defines nozzle layouts and fixturing, and optimises pump sizing and filtration. This engineering‑led approach ensures each parts cleaning machine delivers high performance with minimal downtime.

From compact cabinet units to large heavy duty parts washers integrated with robots or conveyors, all systems are built for industrial duty, easy maintenance and reliable operation over many years.

Technical Options and Customisation

Because every plant and part family is different, each automotive parts washing machine can be customised:

- Single or multi‑stage industrial parts washing machines (wash, rinse, rust‑prevent, dry).

- Aqueous‑based chemistries in a closed‑loop parts washer for safer, environmentally responsible operation.

- Integration with conveyors, gantries or robots for automatic loading and unloading.

- Optional monitoring of conductivity, pH and temperature for critical component washing machines.

These options allow the same core platform to be used from prototype lines to high‑volume series production.

FAQ – Automotive Parts Washing Machines

What is an automotive parts washing machine?

An automotive parts washing machine is an engineered industrial parts washer used to remove oil, chips, dust and other contaminants from vehicle components before assembly, coating or packing. It automates the washing, rinsing and drying process so parts consistently meet specified cleanliness levels.

How do I choose the right type of parts washer?

The right parts washer depends on part size and geometry, contamination type, required cleanliness, and desired cycle time. For high‑volume inline cleaning, a conveyorised industrial parts washing machine is usually preferred, while rotary basket or cabinet‑type automatic parts washers suit batch cleaning of smaller components.

Can one machine clean different automotive components?

Yes, a single parts cleaning machine can often clean multiple components, provided fixtures and baskets are designed correctly. Different wash “recipes” can be stored in the control system so that the auto parts washer automatically adjusts time, temperature and pressure for each part family.

Are these parts washers compatible with aqueous detergents?

Most modern industrial parts washers are designed as aqueous systems, using water‑based detergents instead of solvents. An aqueous component washing machine with proper filtration and oil separation is safer for operators, easier to maintain, and more environmentally friendly.

What makes a parts washer heavy duty?

A heavy duty parts washer uses higher‑capacity pumps, stronger structures, and more robust fixtures to handle large or heavily contaminated parts. These machines are built for long operating hours, high loads, and demanding conditions commonly found in automotive foundries and machining shops.

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |