Aerospace Parts Cleaning Machine

Aerospace Parts Cleaning Machine for Critical Aviation Component Cleaning

An aerospace parts cleaning machine is a precision cleaning system designed to meet the stringent cleanliness requirements of aviation and aerospace manufacturing, maintenance, repair and overhaul (MRO) operations. These machines remove oils, greases, machining fluids, carbon deposits and contaminants from critical components such as engine parts, landing gear, hydraulics and avionics without damaging sensitive surfaces or coatings.

What Is Aerospace Parts Washing?

Aerospace parts washing is the process of cleaning aviation components to remove all traces of contamination that could compromise performance, safety or assembly quality. Unlike general industrial cleaning, aerospace cleaning requires:

- Critical cleanliness levels: Parts must meet ultra-low contamination limits (measured by NVR, particle count or visual inspection).

- Material compatibility: Cleaning must not damage precision surfaces, coatings, composites or delicate geometries.

- Validated processes: Cleaning cycles must be documented and validated to meet OEM specifications and regulatory standards.

An aerospace washing machine is engineered specifically to meet these requirements, using controlled processes, appropriate chemistries and validated cycles.

Aerospace Cleaning Machine – Key Applications

An aerospace cleaning machine is used across a wide range of aviation and aerospace applications:

- Engine Components : Cleaning of turbine blades, blisks, rotors, stators, fan blades, combustion chambers, fuel nozzles and HPT (high-pressure turbine) parts.

- Landing Gear & Wheels: Removal of hydraulic oil, grease, rubber dust, cement and brake dust from landing gear assemblies, struts, wheels and brake components.

- Hydraulics & Actuation: Precision cleaning of hydraulic pumps, valves, actuators and flight control components to aerospace cleanliness standards.

- Avionics & Electronics: Gentle cleaning of electronic assemblies, connectors and sensors without damaging delicate components.

- Additive Manufactured Parts: Removal of powder residues and support material from 3D-printed aerospace components.

- MRO Operations: Cleaning during maintenance, repair and overhaul cycles to prepare parts for inspection, coating or reassembly.

Aerospace Grade Cleaning Machine – Technologies

An aerospace grade cleaning machine can use one or more cleaning technologies depending on part geometry and contamination:

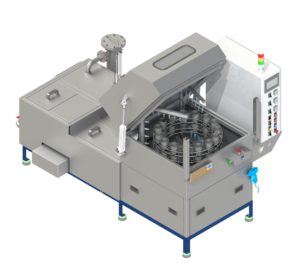

- Ultrasonic Cleaning: High-frequency sound waves create cavitation bubbles that remove contaminants from complex geometries, blind holes and internal passages—ideal for turbine blades, fuel injectors and precision components.

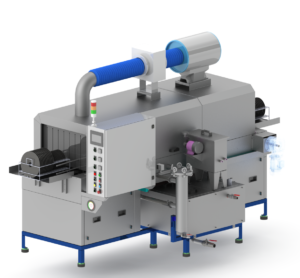

- Spray Cabinet Washers: High-pressure aqueous spray in enclosed cabinets for larger parts like landing gear, wheels and structural components.

- Rotary Basket Washers: Parts rotate inside a basket while spray manifolds deliver cleaning solution from multiple angles—effective for batch cleaning of fasteners, fittings and small parts.

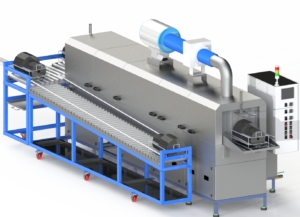

- Tunnel / Conveyor Washers: Continuous-flow systems for high-volume aerospace parts washing with multiple wash, rinse and drying zones.

- Vapor Degreasing: Solvent-based cleaning using heated vapors for critical cleaning of oxygen systems, gas components and parts requiring removal of heavy greases and non-polar residues.

All systems can be configured with deionized (DI) water rinse, heated drying and validation support to meet aerospace specifications.

Aerospace Parts Cleaning Machine – Typical Specifications

Adjust to match aerospace cleaning requirements:

Specification | Value (example) | Notes |

System type | Ultrasonic / spray cabinet / rotary / tunnel | Based on part size and volume |

Application | Engine parts, landing gear, hydraulics, avionics | Aerospace parts cleaning machine |

Cleaning method | Aqueous / ultrasonic / vapor degreasing | Material and contamination-dependent |

Cleanliness target | NVR < 1 mg/dm², particle count per spec | Aerospace OEM requirements |

Process stages | Wash / DI rinse / final rinse / heated dry | Multi-stage for critical cleaning |

Water quality | DI water (1–10 MΩ·cm) for final rinse | To prevent mineral deposits |

Drying system | HEPA-filtered hot air / vacuum drying | Complete drying for aerospace |

Controls | PLC + HMI with recipe, data logging | For validation and traceability |

Construction | Stainless steel, passivated surfaces | Contamination-free environment |

Validation support | IQ/OQ/PQ, FAT/SAT documentation | For ISO, FAA, OEM compliance |

Why Choose an Aerospace Parts Cleaning Machine?

Investing in a dedicated aerospace parts cleaning machine provides clear benefits for aviation and aerospace manufacturers:

- Regulatory compliance: Validated cleaning processes meet ISO, FAA and OEM specifications for critical aerospace components.

- Consistent quality: Automated, repeatable cycles eliminate variability and ensure every part meets cleanliness requirements.

- Reduced rework: Proper cleaning the first time reduces failures, contamination-related defects and costly rework.

- Material compatibility: Aerospace-grade chemistries and controlled processes protect delicate coatings, composites and precision surfaces.

- Lower operating costs: Optimized water, chemistry and energy usage reduce per-part cleaning costs over time.

Frequently Asked Questions

What is the difference between aerospace parts cleaning and general industrial cleaning?

Aerospace parts cleaning requires ultra-high cleanliness levels (measured by NVR, particle count or visual standards), validated processes, material-safe chemistries and compliance with OEM and regulatory specifications. General industrial cleaning may not meet these critical aerospace requirements.

What cleaning method is best for aerospace engine components?

For complex engine components like turbine blades and fuel nozzles, ultrasonic cleaning is often preferred because it reaches internal passages and complex geometries. For larger parts like casings and landing gear, spray cabinet or rotary basket aerospace washing machines are more suitable.

Can one aerospace cleaning machine handle different part types?

Yes. A well-designed aerospace parts cleaning machine with programmable recipes, adjustable pressure and multiple rinse stages can handle turbine blades, landing gear, hydraulics and avionics by storing different validated cycles for each part family.

How is cleaning validated for aerospace applications?

Cleaning validation for aerospace parts washing involves defining cleaning cycles, challenging with worst-case contamination, and verifying cleanliness through methods like NVR (non-volatile residue) testing, particle counting, visual inspection and surface analysis. The PLC records all cycle parameters for traceability.

Where can I find aerospace grade cleaning machine manufacturers?

Ultramax Hydrojet manufactures aerospace parts cleaning machines and aerospace grade cleaning systems tailored for aviation component manufacturers and MRO operations. We supply ultrasonic, spray cabinet and custom multi-stage systems with DI water, validation support and compliance with aerospace specifications. Contact us in Chennai for aerospace cleaning solutions.

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |