Bin Cleaning Machine

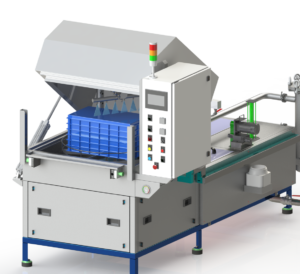

Bin Cleaning Machine for Industrial Bin and Tote Washing

A bin cleaning machine is an automated system designed to wash, rinse and dry reusable industrial bins, totes, IBC containers and pallets used in food processing, pharmaceuticals, logistics and manufacturing. These machines remove product residues, labels and contaminants, ensuring bins meet hygiene standards for immediate reuse.

Available in rotary and conveyor configurations, a bin washing machine delivers high-throughput, consistent cleaning with minimal manual labour, helping operations maintain hygiene compliance, reduce waste and extend bin service life.

What Is a Bin Washing Machine?

A bin washing machine automates the cleaning of large containers through multiple stages:

- Pre-wash: High-pressure spray removes bulk debris, labels and loose contamination.

- Main wash: Heated detergent solution at controlled temperature and pressure cleans all interior and exterior surfaces.

- Rinse: Hot or cold water rinse removes detergent and residues.

- Drying: Blow-off nozzles or hot air drying ensures bins exit ready for stacking or immediate reuse.

Depending on throughput and layout, the bin cleaning system can be configured as a rotary indexing machine or a continuous conveyor line.

Rotary Bin Cleaning Machine – Batch Processing

A rotary bin cleaning machine uses a rotating turntable or carousel that indexes bins through fixed spray zones. Bins are loaded onto the turntable, which rotates step-by-step through wash, rinse and dry stations.

Advantages of rotary bin washers:

- Compact footprint, ideal for facilities with limited floor space.

- Simple loading and unloading from one side or front access.

- Lower initial cost than full conveyor lines, suitable for medium throughput (30–60 bins/hour).

- Easy integration into existing bin return areas.

Rotary systems work well when bins arrive in batches rather than continuous flow, making them popular in food processing plants and smaller logistics centres.

Conveyor Bin Washing System – High-Throughput Inline Cleaning

A conveyor bin washing system uses a belt or chain conveyor that carries bins continuously through a tunnel with dedicated pre-wash, wash, rinse and drying zones. Bins are loaded at one end and exit clean and dry at the other.

Advantages of conveyor bin washers:

- High throughput (60–120+ bins/hour) for continuous operation.

- Inline integration with bin return or logistics lines, minimising manual handling.

- Longer spray zones allow more aggressive cleaning and better rinsing.

- Scalable design—add zones or increase speed to match production growth.

Conveyor systems are ideal for large-scale food plants, pharmaceutical facilities and distribution centres with constant bin circulation.

Bin Cleaning System – Key Features

Whether rotary or conveyor, a well-designed bin cleaning system includes:

- High-pressure spray manifolds positioned to cover bin interiors, exteriors, corners and handles.

- Temperature-controlled wash baths with filtration, oil separation and overflow weirs.

- PLC control with recipe management for different bin sizes and contamination levels.

- Stainless steel construction and HACCP/cGMP-compliant design for food and pharma applications.

- Both rotary and conveyor bin cleaning equipment can include optional label removal, detergent dosing and extra drying stages.

Bin Cleaning Machine – Typical Specifications

Choose rotary for batch/medium volume; choose conveyor for continuous/high volume.

Specification | Rotary bin washer (example) | Conveyor bin washer (example) |

Machine type | Indexing rotary turntable | Continuous belt/chain conveyor |

Bin sizes | Up to 1200 × 1000 × 800 mm | Up to 1200 × 1000 × 800 mm |

Throughput | 6-10 bins/hour | 60–120 bins/hour |

Process stages | Pre-wash / Wash / Rinse / Dry | Pre-wash / Wash / Rinse / Dry |

Spray pressure | 3–8 bar (adjustable) | 3–8 bar (adjustable) |

Heating system | Electric | Electric |

Operating temperature | 50–75 °C | 50–75 °C |

Controls | PLC + HMI | PLC + HMI with line integration |

Construction | Stainless steel | Stainless steel |

Footprint | Compact (1.5× 1.5 m typical) | Larger (5+ m length) |

Applications – Where Bin Cleaning Machines Are Used

Bin cleaning equipment is essential in:

- Food processing: Washing meat bins, bakery trays, dairy crates and produce totes to meet HACCP standards.

- Pharmaceuticals: Cleaning ingredient bins, IBC totes and material transfer containers to cGMP requirements.

- Logistics and distribution: Washing reusable totes, pallets and returnable transport packaging.

- Manufacturing: Cleaning parts bins, chemical totes and bulk material containers.

Both rotary and conveyor bin washing systems improve hygiene, reduce labour and keep assets in circulation.

Bin Cleaning Machine for Sale – Choosing the Right System

When evaluating a bin cleaning machine for sale, consider:

- Throughput: Rotary systems suit 30–60 bins/hour; conveyor systems handle 60–120+ bins/hour.

- Bin variety: Ensure the machine handles your largest bins and totes; both systems can be configured for multiple sizes.

- Space and layout: Rotary machines fit tight spaces; conveyor systems need linear floor space but integrate easily into material flow.

- Hygiene standards: For food and pharma, specify stainless steel, sanitary spray arms and compliance documentation.

A properly sized bin washing machine is an investment in hygiene, efficiency and compliance, not just a purchase.

Bin Wash Systems Price – What Determines Cost

The bin wash systems price depends on:

- Configuration: Conveyor systems cost more than rotary due to longer tunnels and conveyors, but deliver higher throughput.

- Capacity: Higher-capacity machines with multiple zones, faster cycles and automated loading/unloading increase cost.

- Construction: Stainless steel, HACCP/cGMP compliance and sanitary design add price but are essential for regulated industries.

- Customisation: Label removal, detergent dosing, extra drying and conveyor integration raise cost but improve efficiency.

Contact Ultramax Hydrojet for detailed quotations on rotary or conveyor bin cleaning systems based on your throughput, bin types and facility layout.

Frequently Asked Questions

What is the difference between rotary and conveyor bin washing machines?

A rotary bin cleaning machine uses an indexing turntable, ideal for batch washing and compact spaces with throughput of 30–60 bins/hour. A conveyor bin washing system uses a continuous belt, suited for high-volume inline operations with throughput of 60–120+ bins/hour.

Which bin cleaning system is better for my facility?

Choose rotary if you have limited floor space, medium throughput and bins arrive in batches. Choose conveyor if you have continuous flow, high throughput and need inline integration with logistics or production lines. Both can meet HACCP and cGMP requirements.

Can one bin washer handle different bin sizes?

Yes. Both rotary and conveyor bin washing machines can be configured with adjustable guides, racks or spray zones to handle multiple bin sizes. The PLC stores different recipes (wash time, pressure, temperature) for each bin type.

What types of bins can be cleaned in these machines?

A bin cleaning machine can wash plastic totes, stainless steel bins, IBC containers, bakery trays, meat bins, produce crates, pallet boxes and returnable transport packaging. The system is tailored to your specific bin portfolio.

Is a bin cleaning system suitable for food and pharmaceutical use?

Ultramax Hydrojet manufactures railway cleaning machines including automatic bogie washing plants, coach washing systems and wheelset cleaning equipment for Indian Railways, metros and transit systems across India. Contact us in Chennai for specifications and site visits.

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |