Railway Cleaning Machine

Railway Cleaning Machine for Automated Train & Bogie Washing

A Railway Cleaning machine is an automated system designed to wash trains, coaches, bogies, wheelsets and undercarriage components used in railway operations. These machines remove dirt, grease, brake dust and contaminants to maintain appearance, ensure safe inspection and comply with railway maintenance standards.

Configured as railway cleaning plants, they deliver high-throughput, water-efficient cleaning for passenger coaches, metro trains, diesel and electric locomotives, and transit car bogies across Indian Railways, metros and depot facilities.

Types of Railway Cleaning Machines

Rail cleaning machines can be categorized based on what they clean:

Coach Washing Plants:

Automated railway cleaning plants for washing the exterior of train coaches, carriages and locomotives. Trains pass through multiple arches with rotating brushes, high-pressure spray nozzles and detergent dosing systems.

- Clean 8–24 coaches in 10–15 minutes with water recycling.

- Suitable for passenger coaches, diesel locomotives and overhead electric (OEL) trains.

- Save 60–70% water compared to manual washing.

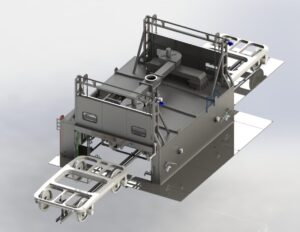

Bogie and Wheelset Wash Plants :

- Specialized rail cleaning machines that clean bogies, wheelsets and undercarriage components before inspection or rebuild.

- Enclosed chamber with high-pressure oscillating spray jets for thorough cleaning.

- Remove grease, brake dust and contaminants from bearings, axles and suspension parts.

- Clean 8–12 bogies per 8-hour shift.

- Available in automatic, semi-automatic and robotic configurations.

Railway Cleaning Plants – How They Work

A typical railway cleaning plant operates in multiple stages:

For Coach Washing:

- Pre-rinse to remove loose dirt and dust.

- Detergent application via spray or foam.

- Brush or high-pressure washing for deep cleaning.

- Fresh water rinse and drying (optional air blow-off).

- The system uses water reclamation and filtration to recycle up to 70% of water, making railway cleaning machines environmentally sustainable.

For Bogie Washing:

- Bogie enters enclosed chamber on rails or turntable.

- High-pressure hot water and detergent spray from oscillating nozzles.

- Rinse cycle with fresh water.

- Moisture removal and drying for quick turnaround.

- PLC control ensures repeatable, programmable cycles for different bogie types and contamination levels.

Rail Cleaning Machines – Key Features

Modern rail cleaning machines include:

- High-pressure spray systems (50–150 bar) with rotating or oscillating nozzles for complete coverage.

- Stainless steel construction for durability in wet, high-use railway depot environments.

- Water recycling and filtration systems to reduce consumption by 60–70%.

- PLC + HMI control with customizable washing programs for different train types (passenger, freight, metro, locomotive).

- Options for hot water, steam, detergent dosing and robotic positioning for sensitive areas.

These features make railway cleaning plants efficient, reliable and compliant with Indian Railways maintenance standards.

Railway Cleaning Machine – Typical Specifications

These systems are tailored to depot layout, train types and throughput requirements.

Specification | Coach washing plant (example) | Bogie/wheelset wash plant (example) | |

System type | Pass-through automatic wash arches | Enclosed chamber with rails/turntable | |

Capacity | 8–24 coaches in 10–15 minutes | 8–12 bogies per 8-hour shift | |

Cleaning method | Brushes + high-pressure spray | High-pressure oscillating spray jets | |

Operating pressure | 30–100 bar | 50–150 bar | |

Water consumption | 60–70% savings vs manual washing | Water recycling with filtration | |

Heating system | Optional hot water / steam | Hot water / steam for degreasing | |

Controls | PLC + HMI, automated cycle | PLC + HMI, programmable recipes | |

Construction | Galvanized/stainless steel | Stainless steel chamber | |

Applications | Passenger coaches, locomotives, metros | Bogies, wheelsets, under-gear parts |

Applications – Where Railway Cleaning Machines Are Used

Railway cleaning plants are essential in:

- Indian Railways: Coach cleaning depots, loco sheds, wagon maintenance facilities and pit lines.

- Metro systems: Daily coach washing for Delhi Metro, Mumbai Metro, Bangalore Metro and other urban transit systems.

- Passenger car rebuild plants: Bogie and wheelset cleaning before inspection and overhaul.

- Freight and transit car facilities: Cleaning of goods wagons and bogie assemblies.

By automating cleaning with rail cleaning machines, railway operators improve efficiency, reduce water use and maintain fleet appearance and safety.

Benefits of Automated Railway Cleaning Machines

Implementing railway cleaning machines offers clear advantages:

- Water conservation: Recycling systems save 60–70% water compared to manual hose washing.

- Labour savings: Automated systems reduce manual cleaning crews and speed up turnaround.

- Consistent quality: Programmable cycles ensure every coach or bogie receives the same thorough cleaning.

- Faster inspections: Clean bogies and wheelsets make defects easier to detect during maintenance.

- Environmental compliance: Wastewater treatment and oil separation systems meet environmental regulations.

Frequently Asked Questions

What is the difference between coach washing plants and bogie washing plants?

A coach washing plant cleans the exterior of train coaches and locomotives as they pass through spray arches and brushes. A bogie washing plant cleans bogies, wheelsets and undercarriage components inside an enclosed chamber with high-pressure jets. Both are types of railway cleaning machines, but serve different maintenance needs.

How much water does a railway cleaning machine save?

Automated railway cleaning plants with water recycling systems save 60–70% water compared to manual hose washing. Filtered and treated water is reused for pre-rinse and wash cycles, with only final rinse requiring fresh water.

Can one railway cleaning plant handle different train types?

Yes. Modern rail cleaning machines use PLC control with multiple programmable recipes to handle passenger coaches, freight wagons, diesel locomotives, electric locomotives and metro trains. Spray patterns, pressure, detergent and cycle times are adjusted per train type.

How many coaches can be cleaned per hour?

A high-capacity coach washing railway cleaning machine can clean 8–24 coaches in 10–15 minutes, allowing 40–100+ coaches per 8-hour shift depending on configuration and train length. This is significantly faster than manual washing.

Where can I find railway cleaning machine manufacturers in India?

Ultramax Hydrojet manufactures railway cleaning machines including automatic bogie washing plants, coach washing systems and wheelset cleaning equipment for Indian Railways, metros and transit systems across India. Contact us in Chennai for specifications and site visits.

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |